Rapid Prototyping vs. Traditional Prototyping: A Comparative Analysis

Key Differences Between Rapid and Traditional Prototyping

Speed and Time Efficiency in Modern Manufacturing

Rapid prototyping gives businesses a huge boost in speed when compared to old school manufacturing techniques. The whole process lets companies test out ideas much faster, sometimes getting working models ready within days instead of waiting weeks or even months like with conventional methods. Many manufacturers report cutting their development time by around 30 to maybe even 50 percent, which really helps them get products to market quicker. Traditional approaches take forever because they involve so many steps in the factory, making it tough to move from idea to actual product without delays. For industries where being first matters a lot, adopting rapid prototyping means shorter wait times and better chances to beat competitors to market with new innovations.

Cost Implications: Short-Run vs. Mass Production

How much something costs depends a lot on how many units need to be made when comparing fast prototyping against old school methods. For small batches where designers keep changing things around, rapid prototyping saves money big time. Take auto part makers for instance they save thousands when producing under 100 pieces because there's no need for expensive molds every time they tweak the design. But once companies start talking about thousands of units, traditional approaches suddenly look better financially. The initial investment in tooling and molds might seem steep at first glance, but spread across tens of thousands of products, those costs disappear pretty quickly. That's why most factories still go with conventional methods when scaling up production beyond certain thresholds despite all the hype around newer technologies.

Design Flexibility and Geometric Complexity

What makes rapid prototyping so appealing is how it lets designers work with all sorts of shapes and forms that would be impossible with old school methods. Take 3D printing for instance, it can produce really detailed parts at a fraction of what traditional manufacturing would cost. The whole process isn't locked into fixed parameters either. Designers can tweak things on the fly during development, something that just doesn't happen much with conventional approaches where changes mean starting over from scratch. This kind of freedom matters a lot when pushing creative boundaries. Artists and product developers alike find they can test wild ideas quickly without worrying about whether those ideas fit within standard manufacturing limitations.

Material Versatility in Sheet Metal Fabrication

Rapid prototyping works with all sorts of materials, opening up lots of possibilities for custom applications in various sectors. Traditional manufacturing methods get stuck with tooling constraints and limited material options, while rapid prototyping lets manufacturers work with plastics, metals, and composite materials. Industry data suggests these systems can manage around 50 different materials, something that regular sheet metal shops just cant do. The ability to choose from so many materials makes a big difference when developing innovative products. For instance, medical device companies can test prototypes with biocompatible materials before final production runs, saving time and money on redesigns later.

Advantages and Limitations of Each Method

Rapid Prototyping Benefits for Automotive Parts Manufacturing

In car part making, rapid prototyping brings real advantages when speed counts most. The process lets engineers test out ideas fast and tweak them without going all in on full scale production right away. This cuts down how long it takes to get products from drawing board to showroom floor. Many shops now run on what's called just-in-time manufacturing, which means less scrap metal lying around and faster response times when customers want something different. Some stats show auto makers have cut design mistakes by around 40% since adopting these methods. That kind of improvement makes sense for both quality control and saving money over time.

Traditional Prototyping Strengths in Structural Integrity

In sectors such as aerospace engineering and building construction, traditional prototyping still plays a critical role because nobody can compromise on structural soundness. The old fashioned way tends to create physical models that really match up with how durable and strong the actual finished item will be. When put through rigorous stress tests, these conventional prototypes tend to hold up better than many of the faster alternatives out there. Research from MIT back in 2021 found that traditional methods kept performing reliably even when pushed to limits, which matters a lot for things like airplane parts or bridge components where failure isn't an option.

Material Constraints in Prototyping Rapid Iterations

Rapid prototyping definitely offers great flexibility but runs into some material limitations that impact how strong the prototypes actually are. The stuff we typically use for rapid prototyping just doesn't hold up to stress quite like metal does in regular prototypes, so this limits where they can be applied when things get tough. Industry experts keep pointing out that knowing about these material characteristics matters a lot. Designers need to find that sweet spot between coming up with creative shapes and making sure whatever gets made will actually work properly in real life situations.

Tooling Requirements and Labor Costs Comparison

Old school prototyping usually means spending big bucks on tooling right from the start, which hits small businesses particularly hard in their wallets. Labor expenses also tend to climb because these projects demand skilled workers and take ages to set up properly. Rapid prototyping changes this equation by cutting down on labor costs thanks to automated systems that crank out parts faster than ever before. The machines handle several tasks at once, so operations run smoother and there's less reliance on hands-on work. For companies needing to test different designs quickly or tweak prototypes on the fly, this approach makes all the difference in both time saved and money spent.

Choosing the Right Prototyping Method

Project Scale and Time-to-Market Considerations

Choosing the right prototyping approach depends on several factors including the scale of the project and how urgent it really is. Big projects tend to benefit from traditional methods because they last longer and involve detailed steps that make sure parts can handle rough handling over time. On the flip side, companies racing against deadlines usually go for rapid prototyping instead. Startups in particular find this approach invaluable when trying to keep pace with what customers want right now. Industry data shows teams working under pressure often get better results with fast prototyping options since they allow quick changes during development and help products reach shelves faster without compromising quality standards.

Industry-Specific Applications: Aerospace vs. Consumer Goods

Different industries approach prototyping in completely different ways because they have such varied goals and standards. Take aerospace for instance where old school prototyping remains king since it meets those tough safety rules and structural demands nobody else cares about. These prototypes need to survive all sorts of brutal tests before anyone even thinks about putting them into service. On the flip side, consumer goods manufacturers love rapid prototyping techniques which let them tweak designs based on what customers actually want versus what engineers think they should want. Market research firms track how these differing approaches shape product development paths across sectors. At the end of the day, whether a company picks slow but safe methods or fast and flexible ones depends entirely on what matters most to them safety first or getting products out there quickly.

Cost-Benefit Analysis for Custom Machining Needs

Knowing how much different prototyping approaches will actually cost matters a lot when trying to spend money wisely on projects. A good look at what works best financially depends mainly on how many units need to be made and how complicated the design is. For smaller runs, rapid prototyping usually comes out ahead in terms of dollars spent, which explains why so many shops go this route for one-off or limited edition work. When talking about big production runs though, old school methods tend to make more sense from a budget standpoint. The numbers don't lie either - smart shops that take time to compare options often save around 25-30% on their prototype spending. That kind of savings makes all the difference in tight markets where every penny counts.

Advanced CNC Solutions for Prototyping Needs

High-Quality CNC Machining for Brass Mechanical Components

When it comes to making those really precise brass parts for mechanical applications, CNC machining just can't be beat, particularly when we need those super tight tolerances. The technology behind this manufacturing approach brings some real advantages to the table. Parts get made faster since there's less waiting around between steps, and overall production costs tend to stay lower compared to other methods. That's why so many shops turn to CNC machines first when prototyping new mechanical designs. Looking at what's happening in the industry these days, more manufacturers are switching to CNC techniques. Why? Because these machines allow engineers to create components that last longer in service. The detailed control over every aspect of the cutting process means fewer defects and better performance from finished products across various industrial sectors.

Five-Axis Custom Machining for Complex Automotive Parts

Five axis custom machining gives manufacturers incredible freedom when making those complicated shapes and detailed geometries needed for today's car parts. The real advantage comes from cutting down on how many times parts need to be set up during production, which saves time and makes prototypes much more accurate. Looking at actual numbers from auto factories shows why shops keep turning to five axis methods for their premium car part prototypes. It's become pretty much standard practice across the industry for anything that requires precision beyond what traditional methods can handle.

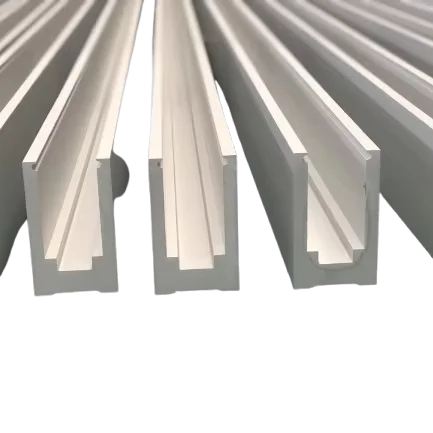

Precision Aluminum Alloy Extrusion Accessories

Aluminum alloy extrusion offers a strong yet light option that works great for building prototypes in industries like aerospace and car manufacturing. The process delivers pretty good accuracy most of the time, which means parts perform consistently when they need to hold together while staying as light as possible. Looking at real world applications, many aircraft manufacturers have turned to aluminum extrusions because they balance price with performance so well. For instance, wing components and fuselage sections often rely on this method since it saves money without compromising safety standards.

Mini CNC Parts for Medical Device Prototyping

Mini CNC machines have become pretty much a must-have in medical device manufacturing these days, especially when it comes to making those tiny parts with intricate details. These little machines can handle all sorts of complicated shapes which means medical products actually meet those tough industry standards they need to pass. Medical regulators really stress how important precision is for prototype development, and we're seeing more hospitals and clinics push for adoption of mini CNC tech across their production lines.

High-Tolerance Aluminum Alloy Turning Services

Turning services deliver high tolerances crucial for precision components in sectors like aerospace and automotive. This capability to maintain exact diameters and surface finishes efficiently meets critical project specifications. Industry surveys highlight that high-tolerance turning has gained preference for producing components that demand exactness in dimensions and quality.

Future Trends in Prototyping Technologies

Integration with Smart Manufacturing (Industry 4.0)

Putting rapid prototyping together with smart manufacturing under Industry 4.0 is changing how factories operate today. When manufacturers connect live data gathering to actual prototype testing, they cut down on wasted time during product development cycles. Smart tech isn't just sitting around collecting numbers anymore it actually helps adjust designs on the fly based on what works best in practice. For shops running production lines, this means getting feedback much faster so changes happen quicker rather than waiting weeks between test runs. Some studies suggest firms adopting these smart approaches see their output jump upwards of 20 percent, though getting there requires proper setup and training across departments. The real value comes from shorter lead times and better products hitting shelves sooner.

Sustainable Materials in Rapid Prototyping Services

Sustainability has become a big deal in product development lately, so many firms are turning to greener materials for their prototypes. What this means practically is that designers are starting to work with things like recycled plastics and plant-based compounds instead of traditional options. These alternatives cut down on waste and pollution while still performing well enough for testing purposes. A lot of businesses see this as a way to check boxes on those international sustainability reports they get pressure to submit. Looking at industry data, there seems to be real momentum behind these eco materials too. Some analysts are talking about around 30 percent growth in usage within five years or so. Beyond just being good for the planet, this approach actually makes sense from a marketing standpoint now that consumers increasingly care about where products come from and how they're made.

Hybrid Approaches Combining Both Methods

The combination of fast prototyping with older, more established methods is becoming increasingly important for manufacturers who want better results without sacrificing quality. When companies mix these approaches, they get the speed advantages of modern techniques but still maintain the reliability that comes from traditional building practices. Think about it this way: products can be tested and refined quickly, yet still hold up under real world conditions. Many professionals in the field have noticed that this mixed approach cuts down on wasted time and money during production runs. For businesses looking to streamline their operations, finding this middle ground between old school craftsmanship and cutting edge technology makes sense both economically and practically speaking.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

LV

LV

SR

SR

SK

SK

UK

UK

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

GA

GA

CY

CY

EU

EU

BN

BN

BS

BS

LA

LA

NE

NE

SO

SO

KK

KK