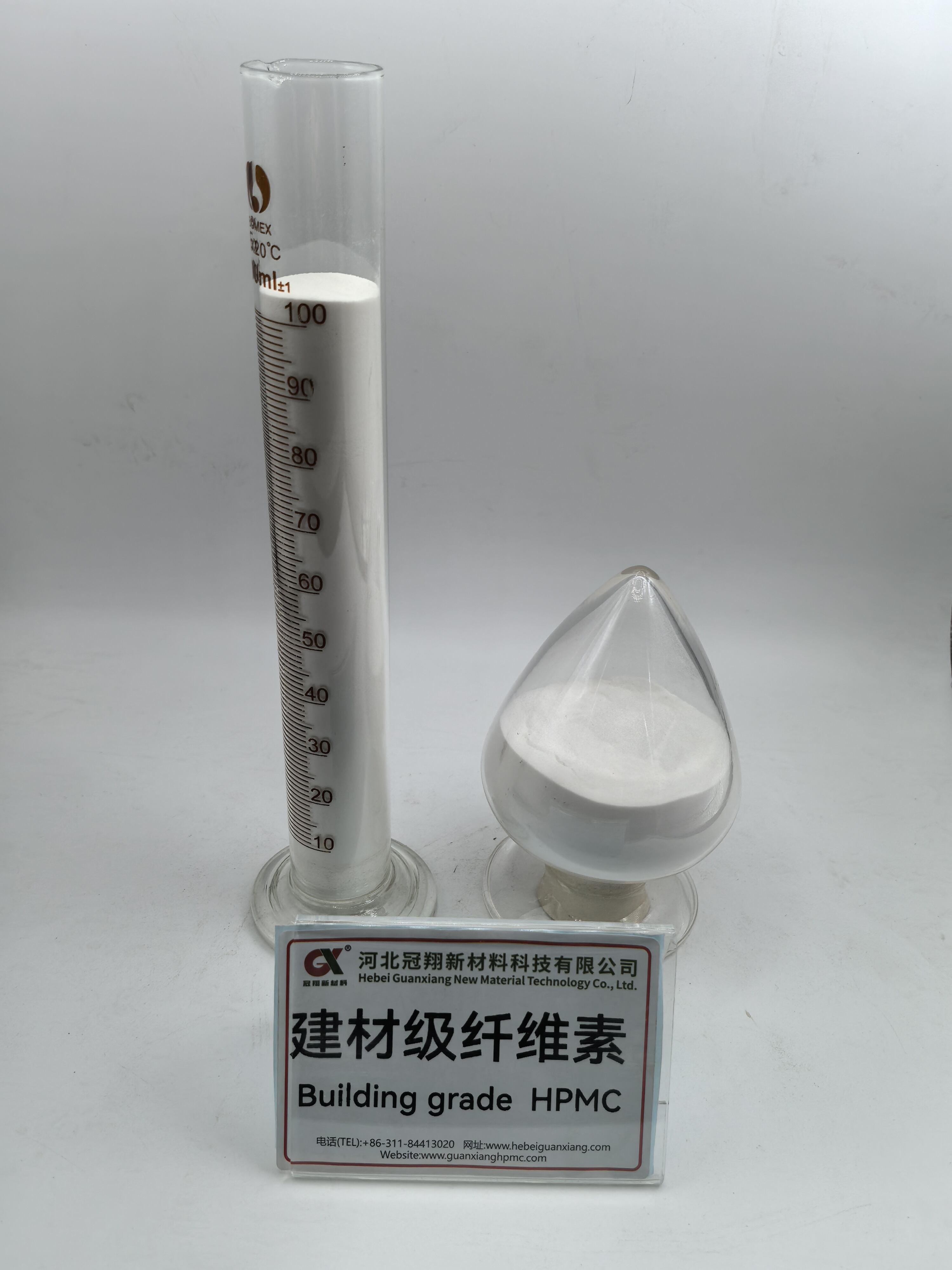

hpmc powder

HPMC powder, or Hydroxypropyl Methylcellulose, is a versatile cellulose ether derivative that plays a crucial role in various industries. This sophisticated compound features unique physicochemical properties that make it indispensable in pharmaceutical, construction, and food applications. As a water-soluble polymer, HPMC powder exhibits exceptional film-forming capabilities and controlled release properties. In pharmaceutical applications, it serves as an essential excipient for drug delivery systems, providing precise control over medication release rates. The construction industry benefits from its superior water retention and workability enhancement properties, particularly in cement-based materials. When used in food products, HPMC powder functions as an effective stabilizer, thickener, and emulsifier, contributing to improved texture and consistency. Its thermal gelation properties make it particularly valuable in low-fat food formulations. The powder's ability to form clear, flexible films has also led to its widespread use in coating applications, from pharmaceutical tablets to food products. With its excellent stability across various pH levels and temperatures, HPMC powder maintains its functionality under diverse processing conditions, making it a reliable choice for manufacturers across multiple sectors.