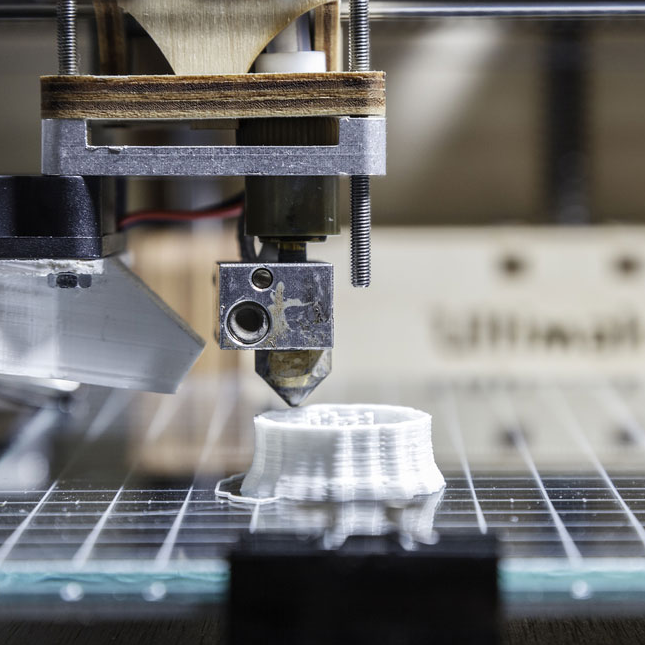

Cost Efficiency of 3D Rapid Prototyping Compared to Traditional Methods

With the continuous improvement of 3D rapid prototyping technologies and techniques, push brand including RMT more to the industry, the product development is no longer strenuous. Various firms now stand to cut on time and resources eliminating the use the traditional and inefficient methods during the prototyping phase. This articles focuses on the cost advantage of using the newer technologies over the older or the basic ones while establishing how innovations at RMT are raising the cost efficiency and performance bar.

Reduced Initial Investment and Setup Costs

One of the most beneficial aspects when compared to other forms of prototyping and hence the more appealing one, 3D rapid prototyping is mostly cost effective. Traditional prototyping methods, such as injection molding or CNC machining, require expensive molds, tooling, and equipment setup. In contrast, RMT's 3D printing solutions eliminate the need for complex tooling and setup, enabling companies to create prototypes directly from digital designs. For small or medium sized enterprises, this means low upfront operational costs, especially.

Production time ensures quick time to market

The traditional prototyping phase can take a number of weeks and sometimes months for the creation of custom molded parts or tooling. The flip side of this is that with traditional tooling and machining processes, the overall time taken for rapid prototyping is only a few days. Advanced 3d printers by RMT make it possible to produce functional prototypes fast, allowing companies to make changes quickly on future designs and perform more tests before going for actual production. These efficiencies result in reduced labor expenses and a faster time to market for product launches.

Reduction inefficiencies in the use of materials and wastage of materials in production process

With positions like these, one can expect long lead times, material wastage as when processes like CNC machining take place to merely remove material to achieve the end goal. 3D printing, on the other hand, has a completely different working principle- it is an additive process, and thus material is placed only where required in order to limit wastage. Using the latest 3d prototyping technologies at RMT, manufacturers will be able to control their wastage and cut their overall material costs particularly in instances when such expensive materials as metals or specialized polymers are needed.

Prototyping with More Complicated Geometries

Creating intricate and more complex geometries by conventional methods sometimes becomes impossible without incurring unreasonable costs. With 3D rapid prototyping however, it is possible to produce precise and detailed components with complex form features that would have been either impossible or too costly to produce through traditional methodologies. 3D printers available with RMT can construct complex designs of prototypes internally rather than assembling multiple pieces which would raise costs in normal processes. This extends the possibility of developing more sophisticated designs in the products without a significant rise in the costs.

Failure Risk Reduction and More Iterations are Possible

One of the problems with conventional prototyping is that it makes it very costly to have so many iterations. Each new prototype may force the use of a new mold or tooling setup which adds more costs. On the contrary, 3D rapid prototyping is not overly time-consuming, meaning several iterations can be made in a matter of hours allowing companies to quickly validate a design before the whole production plant is constructed. The flexible prototyping systems developed by RMT allow the designers to make changes in the design of the parts and try out different material options which minimizes the losses incurred from errors that may occur in the latter stages of production.

Economics for Low Volume Production – Good Value

Traditional techniques seem to be reasonably efficient for mass production but it is a costly option for lower volume runs. The expenses to create molds, the tools and setup for small quantity prototypes or small volume production runs too often seem to have more downsides. RMT’s 3D rapid prototyping technology is particularly effective for low volume production runs as it is easy to set up and cost of manufacture is very low, making it ideal for industries such as aerospace, automotive and consumer electronics.

Starting from a smaller upfront cost, speed of production, cost of materials, and up to the capability of producing intricate designs, there are sinning benefits with 3D printing. Particularly with companies like RMT on the forefront of innovation, the industries can only look forward to more affordable and better solutions in the prototyping and production scenarios.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

LV

LV

SR

SR

SK

SK

UK

UK

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

GA

GA

CY

CY

EU

EU

BN

BN

BS

BS

LA

LA

NE

NE

SO

SO

KK

KK