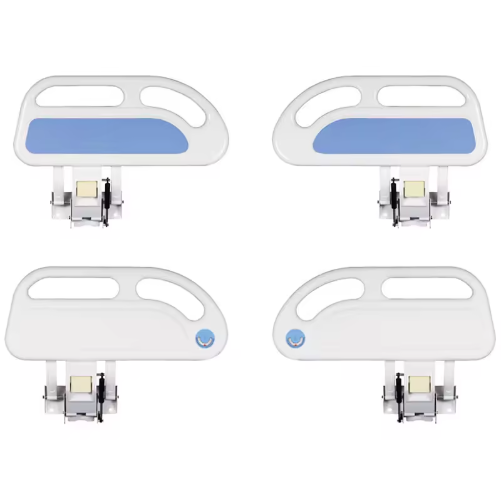

Custom CNC Machining ABS Medical Bed Rail Bracket

Our custom CNC machined ABS medical bed rail brackets are engineered for reliability and safety. They are produced with high precision to ensure perfect fit and function. The medical-grade ABS material offers excellent strength and durability. We provide full customization to meet specific design requirements, making us an ideal manufacturing partner for your precision components.

- Overview

- Inquiry

- Related Products

- Material :High-strength aluminum alloy 6061/7075 or medical-grade ABS/PP.

- Process: 5-axis CNC machining, precision injection molding.

- Key Advantage: Features a self-locking safety mechanism, robust yet lightweight construction, and a smooth surface for easy cleaning and disinfection .

- Precision: Micron-level accuracy (e.g., ±0.1 mm) ensures smooth sliding and secure locking.

- Tolerance: Strict tolerance control within ±0.2 mm for consistent batch quality.

- Surface Finish: Smooth polishing (Ra ≤0.8), with options for anti-bacterial coating or anodizing for easy cleaning.

- Prototype Lead Time: 3-7 working days.

- Mass Production Lead Time: 2-4 weeks.

- Outcome: Enhanced patient safety with ergonomic design, compliant with medical standards (e.g., ISO 13485), and support for OEM/ODM customization.

Process Flow:

Our medical bed side rails are engineered with precision CNC machining and rigorous assembly control to ensure patient safety and operational reliability.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

LV

LV

SR

SR

SK

SK

UK

UK

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

GA

GA

CY

CY

EU

EU

BN

BN

BS

BS

LA

LA

NE

NE

SO

SO

KK

KK