Custom CNC Machining Aluminum Alloy Endoscope Disinfection Box

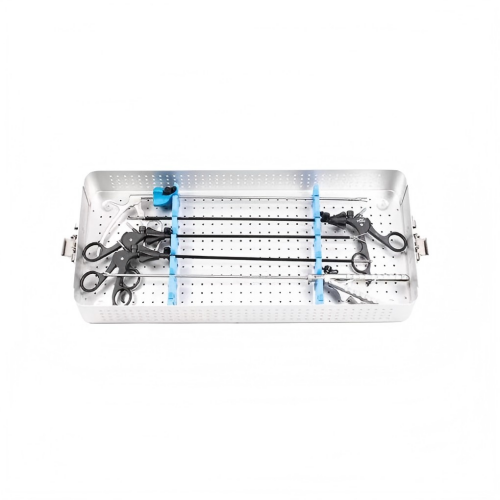

Our Custom CNC Machining Aluminum Alloy Endoscope Disinfection Box ensures the highest level of protection for delicate endoscopes. Manufactured to precise specifications, it offers superior durability, resistance to standard sterilization methods, and secure instrument placement. It's the reliable solution for maintaining instrument integrity and hygiene in demanding medical environments.

- Overview

- Inquiry

- Related Products

- Material:High-Strength Aluminum Alloy (e.g., Al6061-T6).

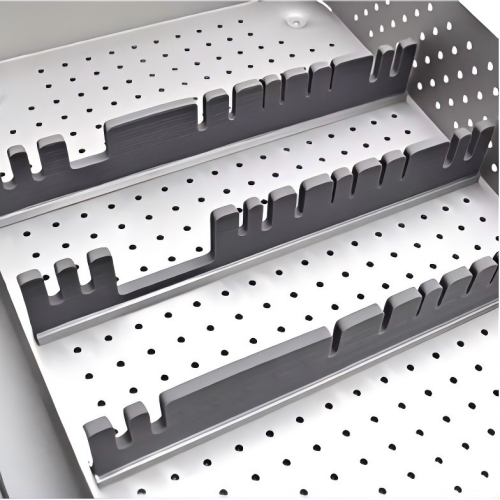

- Process:5-axis CNC machining, precision grinding, anodizing.

- Key Advantage:Features adjustable internal partitions and secure clamping units to prevent instrument collision and cross-contamination, ensuring thorough sterilization and extended instrument lifespan.

- Precision:Micron-level accuracy ensures dimensional perfection and reliable sealing.

- Tolerance:±0.01 mm

- Surface Finish:0.8 Ra, anodizing (various colors available) for excellent corrosion resistance and easy cleaning.

- Prototype Lead Time:5-10 working days

- Mass Production Lead Time:15-20 working days, depending on quantity.

- Outcome:A durable, reusable sterilization solution that enhances workflow efficiency in healthcare settings and provides maximum protection for valuable endoscopes.

Process Flow:

Our endoscope disinfection boxes are defined by the precision of our CNC machining process, ensuring superior protection for delicate medical instruments.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

LV

LV

SR

SR

SK

SK

UK

UK

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

GA

GA

CY

CY

EU

EU

BN

BN

BS

BS

LA

LA

NE

NE

SO

SO

KK

KK