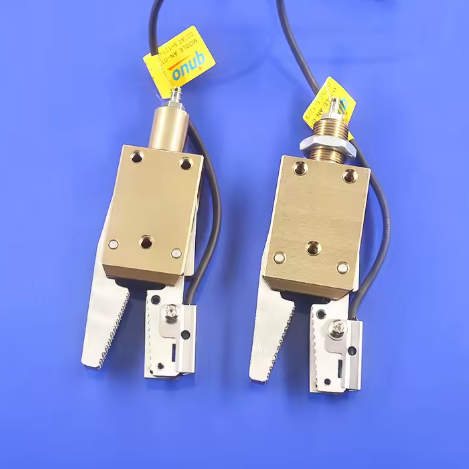

Custom CNC Machining Mini Tower Gripper for Robotic Systems

This mini tower gripper is built for robotic systems requiring precision and reliability. With a compact design and aluminum alloy construction, it handles delicate tasks like electronics assembly or part sorting. Customizable dimensions and surface finishes are available to meet specific automation needs. Perfect for high-volume production environments.

- Overview

- Inquiry

- Related Products

- Material: High-strength aluminum alloy 7075-T6.

- Process:: 5-axis CNC machining.

- Key Advantage: Excellent strength-to-weight ratio, compact structure, supports complex, lightweight geometries, and achieves high repeat positioning accuracy.

- Precision:: Micron-level accuracy ensures dimensional perfection and structural integrity.

- Tolerance: ±0.01 mm.

- Surface Finish: 0.6 Ra, anodizing or powder coating.

- Prototype Lead Time:: 1-5 days.

- Mass Production Lead Time: 1-2 weeks.

- Outcome: Enhances operational precision, stability, and production efficiency for robotic automation systems, ideal for high-precision assembly and handling tasks.

Process Flow:

The performance of our mini tower gripper is defined by a meticulous CNC machining process:

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

LV

LV

SR

SR

SK

SK

UK

UK

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

GA

GA

CY

CY

EU

EU

BN

BN

BS

BS

LA

LA

NE

NE

SO

SO

KK

KK