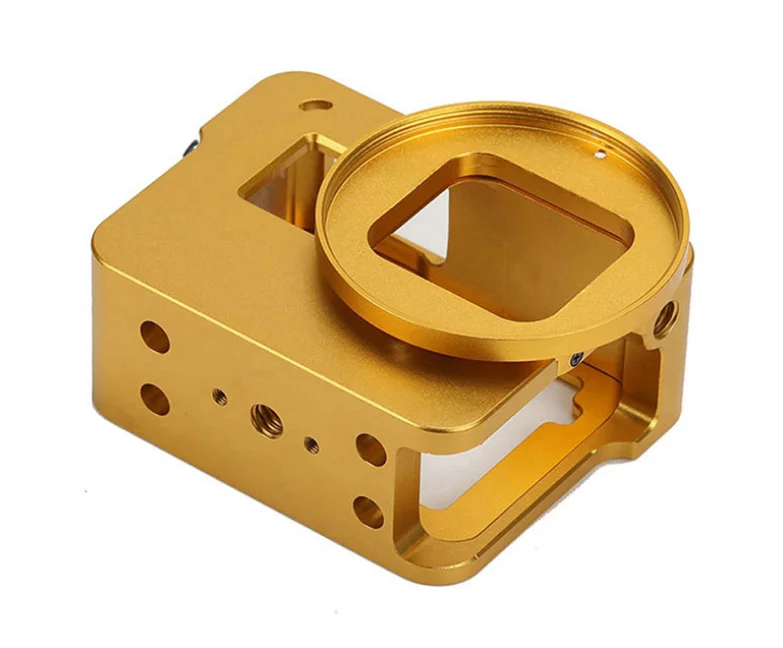

Factory custom machining CNC machining milling aluminum alloy Natural color oxidation Color oxidation turning parts

RMT offers factory custom machining solutions with advanced CNC machining milling techniques for aluminum alloy parts. Our expertise extends to natural color oxidation and color oxidation processes, providing enhanced durability and corrosion resistance for turning parts. With a focus on precision and quality, we specialize in creating custom aluminum alloy components that meet the specific needs of various industries. Whether you're looking for intricate CNC milling or high-quality turning parts, RMT ensures each piece is crafted to the highest standards.

- Overview

- Inquiry

- Related Products

- CNC Machining Milling: RMT utilizes advanced CNC machining milling technology to produce precise, complex components from aluminum alloy with excellent accuracy and surface finish.

- Aluminum Alloy: Known for its lightweight and strong properties, aluminum alloy is ideal for a wide range of applications, and RMT ensures high-quality machining to meet your specific requirements.

- Natural Color Oxidation: Our natural color oxidation process enhances the surface of aluminum alloy components, providing a durable, corrosion-resistant finish without altering the material's appearance.

- Color Oxidation: For added customization, we offer color oxidation to provide a variety of finishes that not only enhance the aesthetic appeal but also improve the longevity of the parts.

- Turning Parts: RMT’s turning parts are manufactured with high precision, ensuring superior quality and functionality for a wide range of applications.

- Aerospace Industry: With the lightweight strength of aluminum alloy and the durability of natural color oxidation, these parts are ideal for aerospace applications requiring high performance and resistance to harsh conditions.

- Automotive Parts: RMT provides turning parts and CNC milling services for the automotive sector, producing components that meet stringent industry standards for safety and performance.

- Electronics: The precision of CNC machining milling and aluminum alloy components ensures that they are perfect for use in electronic devices, offering both functional and aesthetic benefits.

- Industrial Machinery: Our aluminum alloy turning parts and color oxidation treatments make these parts ideal for industrial machinery, ensuring long-term durability and resistance to wear and tear.

- Consumer Goods: From high-quality CNC milling to turning parts, RMT’s custom machining solutions are perfect for a wide variety of consumer products, enhancing both form and function.

Key Features:

Applications:

With RMT’s advanced CNC machining milling and color oxidation capabilities, we offer precision-engineered solutions for aluminum alloy and turning parts across industries, ensuring quality and durability in every component we produce.

|

Process Technology

|

CNC milling

|

CNC Turning

|

CNC Drilling

|

EDM

|

Grinding

|

Tap threads

|

|

Surface treatment service

|

Deburing

|

Polishing

|

Anodizing

|

Electro-plating

|

Powder coating

|

Laser etching

|

|

Quantity support

|

MOQ: 1 PCS

|

10,000 PCS

|

||||

|

Quality standard

|

ISO 9001

|

ISO 14001

|

IATF 16949

|

RoHS

|

SGS

|

|

|

Tolerance

|

-0.01mm +0.01mm

|

-0.02mm +0.02mm

|

-0.05mm +0.05mm

|

-0.1mm +0.1mm

|

||

|

Inspection tools

|

Callipers

|

CMM

|

Projector

|

Height gauge

|

Thread gauge

|

Ring Gauge

|

|

Lead time

|

3 days to 2 weeks

|

|||||

|

Payment Term

|

T/T

|

L/C

|

Paypal

|

Western Union

|

||

|

Shipment

|

EXW

|

DHL

|

FedEx

|

UPS

|

Air Express DDP

|

Ocean freight DDP

|

|

Aluminum Material

|

AL2024

|

AL5052

|

AL 6061

|

AL 6063

|

AL 6082

|

AL 7075

|

|

Stainless steel Material

|

SS 201

|

SS 303

|

SS 304

|

SS 316L

|

SS 17-4PH

|

|

|

Brass Material

|

C22000

|

C24000

|

C28000

|

C36000

|

C37100

|

C37700

|

|

Titanium Material

|

Ti-6Al-4V

|

TA1-TA15

|

TC4

|

TC21

|

GR1

|

GR23

|

|

Sheet Material

|

AL2024

|

AL5052

|

SPCC

|

SGCC

|

galvanized Steel

|

SUS 304

|

|

Plastic Mateiral

|

ABS

|

POM

|

PEEK

|

Acrylic

|

PEEK

|

PC

|

Q. Are you trading company or factory ?

A. We are factory.

Q. How can i customize products?

A. Send us your CAD drawings, and your requests of material, Quantityand surface treatment if needed.

Q. How can i get a quotation?

A. Please provide the CAD drawings, advice quantity and surface treatment. We will send you quotation in 24 hours.

Q. How long is your delivery time?

A. Generally it is 3-10 days. lt also depends on quantity and geometry of parts

Q. How you guarantee the quality?

A. Our production will be strictly follow with the CAD drawing and customers'regquirements.During production and before shipping, we will keep you informedwith photos. We will send you inspection report as well.

Q. What is your terms of payment ?

A. Normally 50% deposit advance, and 50% balance before shipping, T/TWestern Union, Paypal.

Q. How about the transportation?

A. By Express (FedEx, DHL, UPS, TNT) 2-5 days, and by other air freight orocean freight per your request.We have discount account of FedEx and DHLwhich could save lots of shipping cost.

Q. What if the products we received are not good?

A. Almost all products are accepted by our clients. lf there is anything not good. plese contact us without any hesitation.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

LV

LV

SR

SR

SK

SK

UK

UK

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

GA

GA

CY

CY

EU

EU

BN

BN

BS

BS

LA

LA

NE

NE

SO

SO

KK

KK