Innovations in Sheet Metal Fabrication Techniques

Technological Breakthroughs in Sheet Metal Fabrication

Automation & Robotics in Precision Manufacturing

Bringing automation and robotics into precision sheet metal work has completely changed how this sector operates. When factories start using robots, they see better results because machines don't get tired or distracted like humans do, so products come out consistently good quality most of the time. Industry numbers show that automated systems boost production speed around 30% on average while cutting down defects by about a quarter. These kinds of gains matter a lot for businesses since customers want reliable quality and nobody likes paying extra for mistakes. Smart software takes things even further by looking at all the data from production lines and figuring out when something needs adjusting before problems happen. Companies such as BTD Manufacturing have jumped on board with these tech upgrades not just to keep up with competitors but actually stay ahead in markets where getting parts right the first time makes all the difference between profit and loss.

3D Printing for Rapid Prototyping Services

The rise of 3D printing tech is changing how companies approach rapid prototyping services, especially when it comes to making metal parts. What used to take weeks now takes just days, which means big money savings and faster responses to what customers want. Take Marlin Steel Wire Products for instance they switched to 3D printing for their custom metal components and saw costs drop dramatically while production time shortened significantly compared to old school methods. The real game changer though is all the creative freedom this technology brings. Businesses aren't limited anymore to standard shapes and sizes. They can experiment with complex geometries and intricate designs that simply weren't feasible before, completely reshaping how products get made in industries ranging from aerospace to medical devices.

Laser Cutting Advancements in Automotive Parts

The latest improvements in laser cutting tech are changing how automotive parts get made, bringing better accuracy and saving materials at the same time. With these new technologies, factories can now cut out complicated shapes while generating far less waste, which is good news for both company budgets and the environment. Some studies show that when using lasers instead of traditional methods, material usage goes up around 20 percent. That kind of efficiency explains why big names in the business, including companies like Ryerson Holding Corp, have started switching over to laser systems. They're finding all sorts of advantages, from being able to experiment with different designs more freely to speeding up their production lines. The end result? Better quality parts going into cars across the country.

High-Strength Aluminum 5052 Alloys

The 5052 aluminum alloy has become pretty popular among fabricators lately, particularly when making parts for cars. What makes this material stand out? Its impressive combination of strength and lightness really helps improve how vehicles perform while also cutting down on gas usage. Car makers can build lighter frames without sacrificing crash protection thanks to these properties. Another big plus is that 5052 aluminum doesn't hurt the environment much during production and recycles easily at the end of its life cycle. As more companies look for ways to green up their operations, this alloy keeps showing up more frequently in sheet metal work across different sectors.

Corrosion-Resistant 304 Stainless Steel Innovations

304 stainless steel really shines across many different industries because it resists corrosion so well, which means things last longer and save money over time in tough conditions. The material's durability cuts down on how often parts need replacing, saving companies cash in the long run. We see this alloy working great in places where failure just isn't an option, such as surgical tools that must stay sterile between operations or car components exposed to road salt and extreme temperatures. Manufacturers have been making some interesting improvements to stainless steel formulas lately, adding new grades that handle even more challenging situations without breaking down. When looking at both how long stuff lasts and what it costs to maintain, 304 remains one of the top picks for factories trying to balance quality with budget constraints these days.

As industries continue to evolve, the integration of materials like aluminum 5052 and 304 stainless steel plays a pivotal role in advancing sheet metal fabrication techniques, promoting both efficiency and sustainability. Innovative Sheet Metal Solutions in Action

120 Sets Aluminum 5052 for Oilfield Extractors (Washington, USA)

A recent initiative using 120 aluminum 5052 sheet metal components made a real difference in upgrading oilfield extractor systems across several sites in eastern Washington. What makes these parts stand out is their exceptional strength combined with good resistance to wear and tear, which matters a lot when dealing with the rough conditions typical of oil extraction work. People who've worked on the project report noticeable improvements in how efficiently the extractors run day to day. Getting everything produced and delivered wasn't without its headaches though. With such a large order, coordinating shipments became quite a challenge. The team had to develop some pretty solid logistics plans just to keep things moving smoothly. Looking back, this experience serves as valuable lesson for anyone tackling similar projects down the road about why careful planning matters so much when scaling up operations.

100 Sets 5052 Aluminum for LED Lamp Shades (California, USA)

We recently produced 100 sets of LED lamp shades from 5052 aluminum sheets for a client based in California. The design was intentionally simple yet effective, allowing us to streamline production while maintaining quality standards. Aluminum works wonders here because it looks great and functions well too. Clients love how easy it is to recycle after use, which adds value beyond just appearance. These lampshades cut down on waste significantly compared to other materials. Plus they fit right into today's green movement around lighting products. Using aluminum makes sense environmentally speaking since it can be reused multiple times without losing its structural integrity during manufacturing runs.

304 Stainless Steel Parts for Medical Laser Devices

Making 304 stainless steel parts for medical lasers requires strict attention to regulations and safety rules. Getting these components right matters a lot because any flaws could affect how well the medical equipment works or even put patients at risk. During manufacturing, there are real headaches keeping those tiny measurements spot on while still meeting all the medical industry requirements. The team tackled these issues head on though. They implemented better quality checks and adjusted their processes to handle the tight specifications. As a result, they managed to deliver the necessary parts on schedule without cutting corners, which is crucial when lives depend on reliable medical technology.

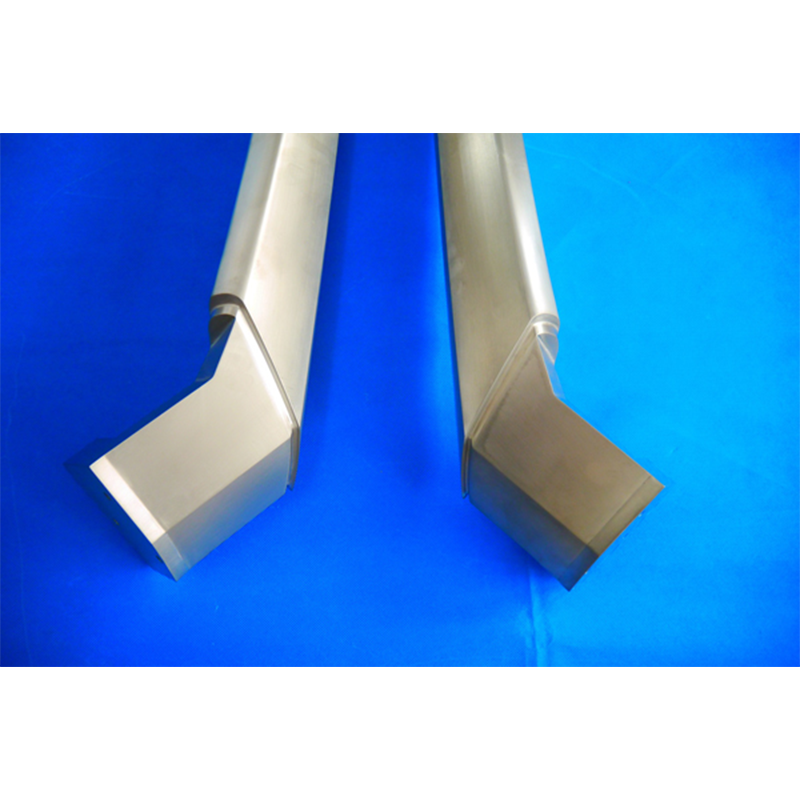

High-Precision CNC Machined Automotive Components

CNC machining is essential for making those super accurate parts needed in cars today. Most shops can hit tolerances down to around 0.01 mm, which makes cars run better and last longer without breaking down so often. Car makers who switch to these precision parts see fewer breakdowns on the road and their assembly lines work smoother too. Look at what happens when companies actually implement this technology properly – failure rates drop dramatically across their product lines. The automotive industry has basically made CNC machining a standard practice because it just works so well for both quality control and keeping production costs under check over time.

Sustainable Practices and Future Trends

Eco-Friendly Fabrication for Car Parts Manufacturing

Green manufacturing techniques are becoming really important in how auto parts get made these days. More companies want to cut down on their impact on the planet by doing things like recycling old materials and running factories that use less power. Take Tesla for instance they actually build cars with stuff that can be reused again and again. BMW is another big name getting serious about cutting waste, especially when it comes to working with sheet metal. There's money to be saved here too. When factories make less trash, they spend less on disposal. Plus, energy bills go down when operations run smarter. People just care more about buying green stuff now than ever before. This has pushed manufacturers to come up with new ways to make their products while sticking closer to nature friendly standards. We're seeing cars and parts being sold based not just on what they do, but how good they are for the environment as well.

IoT Integration in Smart Sheet Metal Factories

Sheet metal fabrication shops are seeing major changes thanks to Internet of Things tech that lets them monitor operations in real time and analyze all sorts of production data. Factories across the industry are starting to adopt these smart systems not just for better efficiency but also to cut down on unexpected shutdowns and fix problems before they become big headaches. Take Siemens and Bosch for instance. Both have rolled out IoT networks throughout their plants where sensors track everything from machine temperatures to tool wear rates. When something starts acting funny, technicians get alerts right away so they can jump on issues before production grinds to a halt. What we're really looking at here is an ongoing transformation in manufacturing spaces. As automation gets smarter and materials science progresses, factories will need to adapt quickly to changing demands. Deeper IoT integration means manufacturers can respond faster to market shifts while keeping inventory levels balanced. Some experts predict this could lead to entirely new approaches to supply chain management over the next decade, though getting there won't be without its challenges.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

LV

LV

SR

SR

SK

SK

UK

UK

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

GA

GA

CY

CY

EU

EU

BN

BN

BS

BS

LA

LA

NE

NE

SO

SO

KK

KK