Why is Sheet Metal Fabrication Essential in Construction?

Critical Role of Sheet Metal Fabrication in Construction

Structural Integrity and Safety Enhancements

Sheet metal fabrication really makes a difference for building projects when it comes to structural strength. The materials used can hold up against all sorts of stresses that buildings face over time. When quality sheet metal goes into construction, it actually reduces the chances of structural problems happening, which explains why so many building codes require it these days. Looking at actual data from the field shows that structures built with proper sheet metal work suffer less damage during earthquakes, storms, and other natural events. That speaks volumes about how durable this approach really is. For ongoing safety though, nobody should forget about routine checks and maintenance on those sheet metal components. Most local authorities have specific requirements about inspecting these systems regularly anyway, so following through just makes good sense both practically and legally speaking.

Customization for Complex Architectural Needs

Sheet metal fabrication gives architects amazing freedom to create custom structures tailored exactly for each project's needs. With modern fabrication methods, designers can now craft complex patterns and unusual shapes that just aren't possible with standard building materials. This really makes buildings stand out visually. Clients love seeing their special design ideas come to life thanks to precise metal work. Different types of metals offer varying properties too, so architects get both form and function when working with sheet metal. This combination lets them turn even wild conceptual designs into actual buildings while maintaining structural integrity throughout the process.

Essential Applications Across Building Projects

HVAC Systems and Climate Control Solutions

Sheet metal is really important when building HVAC systems. It forms the main structure for ducts and various parts that help improve air flow and make the whole system more efficient with energy usage. Sheet metal doesn't break down easily and stands up well against rust, so HVAC installations last longer before needing repairs or replacement. Industry figures suggest that using good quality sheet metal can cut down on energy use by around 30% in many cases, which obviously saves money over time. New advancements in how we fabricate sheet metal have made it possible to create systems that work better in different kinds of buildings, from small offices to large commercial spaces. This flexibility makes sheet metal a key component for managing temperature control effectively while keeping energy costs under control in construction projects.

Protective Exterior Cladding and Roofing

More and more builders are turning to sheet metal for their exterior cladding and roofing needs because it stands up really well against all sorts of weather conditions. The fact that sheet metal isn't heavy but still packs a lot of strength means structures can be lighter on the frame while still getting solid protection from the elements. Some recent data shows buildings with metal cladding tend to hold up better during storms and harsh winters than older buildings made with conventional materials. Plus there's just so many different finish options available these days that architects love playing around with designs without worrying about weakening the structure. That combination of practical benefits plus visual flexibility explains why we see sheet metal everywhere in modern construction projects nowadays.

Precision Structural Components

Sheet metal fabrication done with precision plays a big role in creating structural components for buildings, whether they need to support weight or just serve other functions. With advances in technology today, manufacturers can achieve really tight tolerances so everything fits together just right when putting structures together on site. Getting this level of accuracy means less wasted materials and faster completion times, which saves money especially on big construction jobs. Sheet metal parts made with such precision work well in many different types of building projects from commercial complexes to residential developments. That's why most contractors rely heavily on these fabricated components for their projects. When looking at how modern buildings get constructed efficiently, precision sheet metal work stands out as one of the key factors behind successful execution.

Industry-Leading Fabrication Solutions

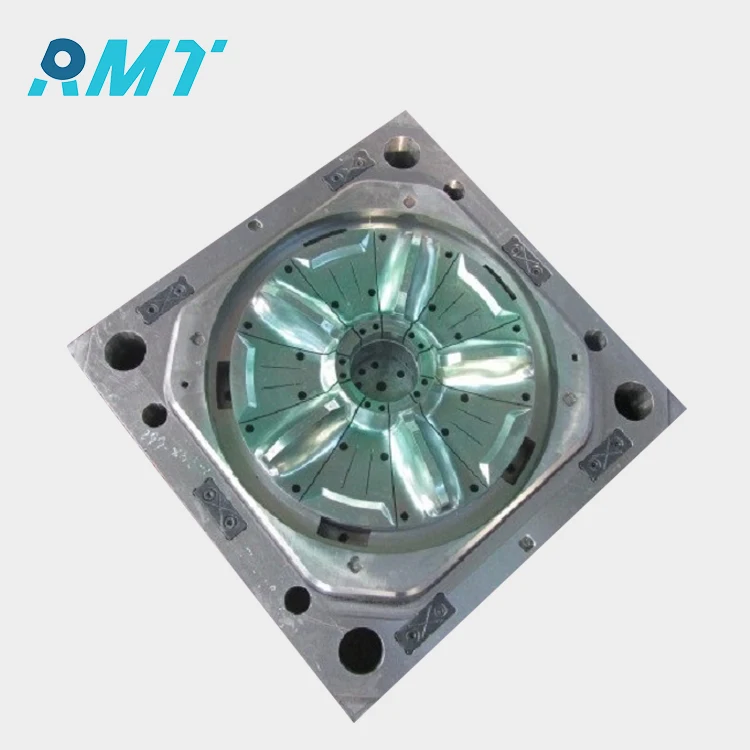

High-Precision CNC Machined Parts Production

CNC machining plays a big role in making those super precise parts needed across construction and manufacturing sectors. What makes this tech stand out? It can copy complex designs again and again without losing quality something regular methods just cant match. Studies show companies that switch to CNC setups typically cut down on production time while their parts end up much more accurate. For businesses thinking about upgrading, getting hold of better CNC machines means they can offer superior products which naturally leads to happier customers in the long run.

Custom Aluminum Alloy Computer Casings

In construction, aluminum alloy casings have become pretty much a must for protecting electronics while keeping things light and tough. These materials conduct both heat and electricity well, so they actually do a good job at controlling temperature issues that can damage sensitive components. According to some market analysis from last year, when companies go for custom made casings instead of standard ones, their equipment tends to last longer because it's better protected from dust, moisture, and other nasty stuff on site. Plus there's something else worth mentioning too – the way these casings look matters a lot now. Contractors love how they can get different colors and finishes applied to match company logos or project themes, making their tools stand out in an increasingly competitive field where appearance counts almost as much as functionality.

CNC Sheet Metal Machine Parts Accessories

Sheet metal work done on CNC machines creates precise components that keep machinery running smoothly. Parts made this way meet tight specifications, which cuts down on breakdowns during operation. When manufacturers can produce these items efficiently, they stay on track with their delivery commitments to suppliers, helping projects move along without delays. As CNC tech keeps improving, we're seeing new possibilities emerge for what sheet metal can do. Recent upgrades in cutting speed and material handling have already expanded what's possible in factory settings across various industries.

Stainless Steel Door Lock Components

When it comes to making door locks that resist corrosion while boosting both security and lasting power in buildings, stainless steel fabrication plays a key role. Using this metal for outside locks means they last longer and save money down the road when replacements become necessary. Industry stats show that locks made with stainless steel see far fewer break ins than regular locks over time. What makes stainless steel so great? Its flexibility lets manufacturers create all sorts of security features tailored to different kinds of structures, from commercial buildings to residential complexes.

Laser-Cut Metal and Stainless Steel Parts

Laser cutting stands out because it can produce extremely precise cuts and handle all sorts of shapes in metal and stainless steel work. What makes this method so appealing is how little scrap material gets wasted during the cutting process, which means manufacturers save money on raw materials and contribute less to landfills. Shops equipped with laser cutters typically finish parts much faster than traditional methods, something that really matters when tight deadlines loom over manufacturing projects. Architects and designers love what they can do with custom laser cuts too, since these intricate patterns allow for distinctive branding features in everything from building facades to interior decor elements.

Technological Advancements Driving Efficiency

Automation in Precision Fabrication

When it comes to precision fabrication work, automation really steps things up a notch when it comes to getting stuff done faster while cutting down on mistakes people make during machining. Factories that bring robots onto their production floors typically see bigger outputs and parts that look pretty much identical every time they come off the line. The numbers back this up too many shops report seeing good money coming back after investing in automation because they're making more products per hour and spending less on wages for workers who used to handle those tasks manually. What's interesting though is how these smart machines actually collect all sorts of useful data along the way. Manufacturers can then look at this information to tweak their designs or adjust when certain jobs get scheduled, which helps everything run smoother overall especially important in industries like sheet metal fabrication where even small efficiencies matter a lot.

Sustainable Manufacturing Practices

Sheet metal fabrication shops across the country are starting to care more about green manufacturing these days, especially when it comes to building projects. Many manufacturers now incorporate scrap metal into their workflows, something that saves money on raw materials while cutting down waste going to landfills. We've noticed a pattern where clients tend to favor contractors who can show they're doing their part for the environment, which naturally builds trust and keeps them coming back for future jobs. Looking at numbers from similar businesses, going green actually pays off over time both in pocketbook savings and better standing within local markets. For most shop owners, conserving resources isn't just good ethics anymore it's becoming essential for staying competitive in today's marketplace.

Rapid Prototyping for Construction Innovation

The construction field is seeing big changes thanks to rapid prototyping methods. These techniques let designers test out their ideas much faster than traditional approaches, which cuts down on how long projects take to complete while also encouraging creative solutions. Architects and engineers now get to play around with different concepts on smaller scales before committing to expensive full builds, something that saves money when mistakes happen early rather than late in the game. Some studies point to development time being slashed by around half with these new methods, giving companies who adopt them a real edge over competitors still stuck in old ways. Plus, digital fabrication equipment brings more adaptability to construction sites. Contractors can tweak designs as they go along without major disruptions, making it easier to incorporate fresh ideas even after work has started on site.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

LV

LV

SR

SR

SK

SK

UK

UK

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

GA

GA

CY

CY

EU

EU

BN

BN

BS

BS

LA

LA

NE

NE

SO

SO

KK

KK